-

Agriculture

Agriculture

-

Health-Care

Health-Care

-

Environment

Environment

-

Construction-Real-Estate

Construction-Real-Estate

-

Tools-Hardware

Tools-Hardware

-

Home-Garden

Home-Garden

-

Furniture

Furniture

-

Luggage-Bags-Cases

Luggage-Bags-Cases

-

Medical-devices-Supplies

Medical-devices-Supplies

-

Gifts-Crafts

Gifts-Crafts

-

Sports-Entertainment

Sports-Entertainment

-

Food-Beverage

Food-Beverage

-

Vehicles-Transportation

Vehicles-Transportation

-

Power-Transmission

Power-Transmission

-

Material-Handling

Material-Handling

-

Renewable-Energy

Renewable-Energy

-

Safety

Safety

-

Testing-Instrument-Equipment

Testing-Instrument-Equipment

-

Construction-Building-Machinery

Construction-Building-Machinery

-

Pet-Supplies

Pet-Supplies

-

Personal-Care-Household-Cleaning

Personal-Care-Household-Cleaning

-

Vehicle-Accessories-Electronics-Tools

Vehicle-Accessories-Electronics-Tools

-

School-Office-Supplies

School-Office-Supplies

-

Packaging-Printing

Packaging-Printing

-

Mother-Kids-Toys

Mother-Kids-Toys

-

Business-Services

Business-Services

-

Commercial-Equipment-Machinery

Commercial-Equipment-Machinery

-

Apparel-Accessories

Apparel-Accessories

-

Security

Security

-

Shoes-Accessories

Shoes-Accessories

-

Vehicle-Parts-Accessories

Vehicle-Parts-Accessories

-

Jewelry-Eyewear-Watches-Accessories

Jewelry-Eyewear-Watches-Accessories

-

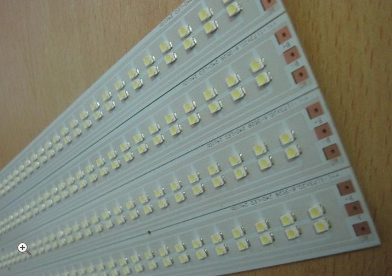

Lights-Lighting

Lights-Lighting

-

Fabric-Textile-Raw-Material

Fabric-Textile-Raw-Material

-

Fabrication-Services

Fabrication-Services

-

Industrial-Machinery

Industrial-Machinery

-

Consumer-Electronics

Consumer-Electronics

-

Electrical-Equipment-Supplies

Electrical-Equipment-Supplies

-

Electronic-Components-Accessories-Telecommunications

Electronic-Components-Accessories-Telecommunications

-

Home-Appliances

Home-Appliances

-

Beauty

Beauty

-

Chemicals

Chemicals

-

Rubber-Plastics

Rubber-Plastics

-

Metals-Alloys

Metals-Alloys

- Masonry Materials

- Curtain Walls & Accessories

- Earthwork Products

- Fireproofing Materials

- Heat Insulation Materials

- Plastic Building Materials

- Building Boards

- Soundproofing Materials

- Timber

- Waterproofing Materials

- Balustrades & Handrails

- Bathroom & Kitchen

- Flooring & Accessories

- Tiles & Accessories

- Door, Window & Accessories

- Fireplaces & Stoves

- Floor Heating Systems & Parts

- Stairs & Stair Parts

- Ceilings

- Elevators & Escalators

- Stone

- Countertops, Vanity Tops & Table Tops

- Mosaics

- Metal Building Materials

- Multifunctional Materials

- Ladders & Scaffoldings

- Mouldings

- Corner Guards

- Decorative Films

- Formwork

- Building & Industrial Glass

- Other Construction & Real Estate

- Wallpapers/Wall panels

- HVAC System & Parts

- Outdoor Facilities

- Prefabricated Buildings

- Festive & Party Supplies

- Bathroom Products

- Household Sundries

- Rain Gear

- Garden Supplies

- Household Cleaning Tools & Accessories

- Lighters & Smoking Accessories

- Home Storage & Organization

- Household Scales

- Smart Home Improvement

- Home Textiles

- Kitchenware

- Drinkware & Accessories

- Dinnerware, Coffee & Wine

- Home Decor

- Golf

- Fitness & Body Building

- Amusement Park Facilities

- Billiards, Board Game,Coin Operated Games

- Musical Instruments

- Outdoor Affordable Luxury Sports

- Camping & Hiking

- Fishing

- Sports Safety&Rehabilitation

- Ball Sports Equipments

- Water Sports

- Winter Sports

- Luxury Travel Equipments

- Sports Shoes, Bags & Accessories

- Cycling

- Other Sports & Entertainment Products

- Artificial Grass&Sports Flooring&Sports Court Equipment

- Scooters

- Food Ingredients

- Honey & Honey Products

- Snacks

- Nuts & Kernels

- Seafood

- Plant & Animal Oil

- Beverages

- Fruit & Vegetable Products

- Frog & Escargot

- Bean Products

- Egg Products

- Dairy Products

- Seasonings & Condiments

- Canned Food

- Instant Food

- Baked Goods

- Other Food & Beverage

- Meat & Poultry

- Confectionery

- Grain Products

- Feminie Care

- Hair Care & Styling

- Body Care

- Hands & Feet Care

- Hygiene Products

- Men's Grooming

- Laundry Cleaning Supplies

- Travel Size & Gift Sets

- Room Deodorizers

- Other Personal Care Products

- Pest Control Products

- Special Household Cleaning

- Floor Cleaning

- Kitchen & Bathroom Cleaning

- Oral Care

- Bath Supplies

- Yellow Pages

- Correction Supplies

- Office Binding Supplies

- Office Cutting Supplies

- Board Erasers

- Office Adhesives & Tapes

- Education Supplies

- Pencil Cases & Bags

- Notebooks & Writing Pads

- File Folder Accessories

- Calendars

- Writing Accessories

- Commercial Office Supplies

- Pencil Sharpeners

- Pens

- Letter Pad/Paper

- Paper Envelopes

- Desk Organizers

- Pencils

- Markers & Highlighters

- Filing Products

- Art Supplies

- Easels

- Badge Holder & Accessories

- Office Paper

- Printer Supplies

- Book Covers

- Other Office & School Supplies

- Stationery Set

- Boards

- Clipboards

- Stamps

- Drafting Supplies

- Stencils

- Electronic Dictionary

- Books

- Map

- Magazines

- Calculators

- Baby & Toddler Toys

- Educational Toys

- Classic Toys

- Dress Up & Pretend Play

- Toy Vehicle

- Stuffed Animals & Plush Toys

- Outdoor Toys & Structures

- Balloons & Accessories

- Baby Food

- Children's Clothing

- Baby Supplies & Products

- Maternity Clothes

- Kids Shoes

- Baby Care

- Novelty & Gag Toys

- Dolls & Accessories

- Puzzle & Games

- Blocks & Model Building Toys

- Toddler Clothing

- Baby Clothing

- Kids' Luggage & Bags

- Arts, Crafts & DIY Toys

- Action & Toy Figures

- Baby Appliances

- Hobbies & Models

- Remote Control Toys

- Promotional Toys

- Pregnancy & Maternity

- Hygiene Products

- Kid's Textile&Bedding

- Novelty & Special Use

- Toy Weapons

- Baby Gifts

- Baby Storage & Organization

- Auto Drive Systems

- ATV/UTV Parts & Accessories

- Marine Parts & Accessories

- Other Auto Parts

- Trailer Parts & Accessories

- Auto Transmission Systems

- Train Parts & Accessories

- Universal Parts

- Railway Parts & Accessories

- Auto Brake Systems

- Aviation Parts & Accessories

- Truck Parts & Accessories

- Auto Suspension Systems

- Auto Lighting Systems

- New Energy Vehicle Parts & Accessories

- Auto Steering Systems

- Wheels, Tires & Accessories

- Bus Parts & Accessories

- Auto Performance Parts

- Cooling System

- Go-Kart & Kart Racer Parts & Accessories

- Air Conditioning Systems

- Heavy Duty Vehicle Parts & Accessories

- Auto Electrical Systems

- Auto Body Systems

- Auto Engine Systems

- Container Parts & Accessories

- Motorcycle Parts & Accessories

- Refrigeration & Heat Exchange Equipment

- Machine Tool Equipment

- Food & Beverage Machinery

- Agricultural Machinery & Equipment

- Apparel & Textile Machinery

- Chemical Machinery

- Packaging Machines

- Paper Production Machinery

- Plastic & Rubber Processing Machinery

- Industrial Robots

- Electronic Products Machinery

- Metal & Metallurgy Machinery

- Woodworking Machinery

- Home Product Manufacturing Machinery

- Machinery Accessories

- Environmental Machinery

- Machinery Service

- Electrical Equipment Manufacturing Machinery

- Industrial Compressors & Parts

- Tobacco & Cigarette Machinery

- Production Line

- Used Industrial Machinery

- Electronics Production Machinery

- Other Machinery & Industrial Equipment

- Camera, Photo & Accessories

- Portable Audio, Video & Accessories

- Television, Home Audio, Video & Accessories

- Video Games & Accessories

- Mobile Phone & Accessories

- Electronic Publications

- Earphone & Headphone & Accessories

- Speakers & Accessories

- Smart Electronics

- TV Receivers & Accessories

- Mobile Phone & Computer Repair Parts

- Chargers, Batteries & Power Supplies

- Used Electronics

- VR, AR, MR Hardware & Software

- Projectors & Presentation Equipments

- Other Consumer Electronics

- Cables & Commonly Used Accessories

- Computer Hardware & Software

- Displays, Signage and Optoelectronics

- Discrete Semiconductors

- Wireless & IoT Module and Products

- Telecommunications

- Connectors, Terminals & Accessories

- Development Boards, Electronic Modules and Kits

- Circuit Protection

- Sensors

- Isolators

- Audio Components and Products

- Integrated Circuits

- Power Supplies

- Relays

- RF, Microwave and RFID

- Electronic Accessories & Supplies

- Passive Components

- PCB & PCBA

- Air Quality Appliances

- Home Appliance Parts

- Heating & Cooling Appliances

- Small Kitchen Appliances

- Laundry Appliances

- Water Heaters

- Water Treatment Appliances

- Refrigerators & Freezers

- Personal Care & Beauty Appliances

- Major Kitchen Appliances

- Cleaning Appliances

- Second-hand Appliances

- Smart Home Appliances

- Other Home Appliances

- Energy Chemicals

- Inorganic Chemicals

- Basic Organic Chemicals

- Agrochemicals

- Admixture & Additives

- Catalysts & Chemical Auxiliary Agents

- Pigments & Dyestuff

- Coating & Paint

- Daily Chemicals

- Polymer

- Organic Intermediate

- Adhesives & Sealants

- Chemical Waste

- Biological Chemical Products

- Surface Treatment Chemicals

- Painting & Coating

- Chemical Reagents

- Flavor & Fragrance

- Non-Explosive Demolition Agents

- Other Chemicals

- Custom Chemical Services

Other Consumer Electronics

Precision LED PCB Assembly for Success

Component Placement and Accuracy

The accuracy of component placement is paramount in LED PCB assembly. Even minor deviations can lead to misalignments, affecting light distribution, thermal management, and overall performance. Automated placement machines, equipped with advanced vision systems, are employed to ensure precise positioning of LEDs and other components. This minimizes human error and guarantees consistent quality across large production runs. Furthermore, the selection of appropriate surface mount technology (SMT) components plays a critical role, as their small size and sensitivity require specialized handling and placement techniques. The use of high-precision stencils further enhances accuracy in solder paste application, minimizing the risk of shorts or solder bridges.

Beyond the placement of the LEDs themselves, the positioning of passive components like resistors and capacitors is equally important. These components directly influence the LED's current and voltage, affecting its brightness, lifespan, and color consistency. Improper placement can result in uneven lighting, premature failure, and costly rework. Therefore, meticulous planning and execution are vital to achieve optimal performance and reliability.

Thermal Management

LEDs generate significant heat, and inadequate thermal management can drastically shorten their lifespan and reduce efficiency. Precision LED PCB assembly incorporates strategies to effectively dissipate this heat. This includes the use of specialized thermal vias, copper pours, and heat sinks directly integrated into the PCB design. These features provide pathways for heat to flow away from the LEDs, preventing overheating and potential damage.

The choice of materials also plays a crucial role in thermal management. High-thermal-conductivity PCBs and specialized solder alloys can enhance heat dissipation. Furthermore, the assembly process itself must be optimized to minimize thermal stress on the components during soldering, preventing damage and ensuring the integrity of the thermal pathways.

Soldering and Inspection

The soldering process in precision LED PCB assembly requires precision and control. Reflow soldering, commonly used for SMT components, necessitates precise temperature profiles to avoid damage to the sensitive LEDs and other components. Under-soldering can result in poor electrical connections, while over-soldering can lead to component damage and short circuits. Automated optical inspection (AOI) systems are often employed to ensure the quality of solder joints, identifying defects and ensuring reliable connections.

Post-assembly inspection is critical to guarantee product quality. Visual inspections, combined with advanced testing methods such as electrical testing and thermal imaging, are used to identify any defects or anomalies that might have occurred during the assembly process. This multi-layered approach minimizes the risk of defective products reaching the end-user, enhancing the reputation and reliability of the manufacturer.

Quality Control and Traceability

Robust quality control measures are integral to precision LED PCB assembly. From incoming material inspection to final product testing, each stage of the process is monitored and documented to maintain consistent quality and traceability. This allows for rapid identification and resolution of any issues that may arise, minimizing production downtime and enhancing overall efficiency.

Implementing a comprehensive quality management system, such as ISO 9001, is crucial for ensuring consistent quality and meeting customer requirements. This involves establishing clear procedures, utilizing calibrated equipment, and maintaining detailed records throughout the entire assembly process. This attention to detail is essential in establishing and maintaining trust with customers and ensuring the long-term success of the business.

Streamlined Flexible Edge Plating Workflow

Enhanced Automation and Robotics

The core of a streamlined flexible edge plating workflow lies in its heavy reliance on automation. Traditional methods often involve manual handling of parts, increasing the risk of human error and slowing down the entire process. A streamlined workflow integrates robotic systems for tasks such as part loading and unloading, pre-treatment processes like cleaning and degreasing, and even the plating process itself. This automation minimizes human intervention in repetitive, potentially hazardous tasks, improving both productivity and worker safety.

Furthermore, advanced robotic arms offer unparalleled precision and consistency in the placement of parts within the plating bath. This precision translates directly to a more uniform plating thickness, reducing defects and improving the overall quality of the finished product. The flexibility inherent in robotic systems allows for easy adaptation to different part geometries and sizes, accommodating diverse production runs without significant retooling or reprogramming.

Intelligent Data Acquisition and Analysis

A truly streamlined workflow goes beyond simple automation; it embraces data-driven decision-making. Sensors and monitoring systems are integrated throughout the process to collect real-time data on critical parameters such as bath temperature, current density, plating thickness, and chemical concentrations. This data is then fed into sophisticated software for analysis, providing valuable insights into the efficiency and effectiveness of the entire process.

This intelligent data analysis allows for proactive identification of potential issues before they escalate into major problems. For example, anomalies in plating thickness can be detected early, allowing for adjustments to the process parameters to prevent defects and reduce waste. The data also provides valuable information for optimizing the workflow, identifying bottlenecks, and predicting maintenance needs, contributing to significant cost savings in the long run.

Modular and Adaptable System Design

Flexibility is paramount in modern manufacturing environments, which often require rapid adaptation to changing product designs and production volumes. A streamlined flexible edge plating workflow achieves this flexibility through a modular system design. Individual modules, responsible for specific tasks within the overall process, can be easily added, removed, or reconfigured to meet evolving needs.

This modularity allows manufacturers to tailor their workflow to specific product requirements without undertaking costly and time-consuming overhauls. For instance, adding a new module for a specific surface treatment or integrating a different type of plating bath can be accomplished with minimal disruption to the overall production line. This adaptability ensures that the workflow remains relevant and efficient even in the face of changing market demands and technological advancements.

Improved Traceability and Quality Control

Maintaining a high level of quality and ensuring traceability are essential in many industries. A streamlined workflow integrates robust tracking and tracing mechanisms, allowing for the complete monitoring of each part throughout the entire process. This data can be used to pinpoint the source of defects, if any, facilitating rapid corrective actions and preventing recurrence.

Furthermore, the consistent data logging and analysis features of the streamlined workflow lead to improved quality control. By setting predefined quality parameters and automating the inspection process, the system can identify and reject substandard parts, minimizing the likelihood of defective products reaching the market. This improved traceability and quality control contribute to a higher level of customer satisfaction and brand reputation.

Reduced Costs and Increased Profitability

The benefits of a streamlined flexible edge plating workflow extend beyond improved efficiency and quality. The reduction in manual labor, minimized waste, and proactive problem solving all contribute to significant cost savings. The increased throughput, facilitated by automation and optimized processes, results in higher production volumes, leading to increased profitability.

Moreover, the reduced defect rate translates into fewer rejects and rework, further reducing costs and enhancing the bottom line. The data-driven insights gained through the intelligent monitoring system allow for continuous improvement, leading to ongoing cost optimization and maximizing the return on investment in the new workflow.

Optimizing Flexible Edge Plating Processes

Substrate Preparation: The Foundation for Success

The success of any plating process hinges on meticulous substrate preparation. For flexible substrates, this is even more critical. The surface must be impeccably clean and free from any contaminants like oils, dust particles, or oxides. These contaminants can impede adhesion and result in poor plating uniformity. Common cleaning techniques involve ultrasonic cleaning with appropriate solvents, followed by rinsing and drying in a controlled environment. The selection of the cleaning solvent and the intensity of the ultrasonic cleaning are crucial parameters that need careful optimization based on the specific substrate material and contaminants.

Furthermore, surface activation is often necessary to improve the adhesion of the plating layer. Techniques like plasma treatment or chemical etching can roughen the surface, creating more anchoring points for the metal deposit. The choice of activation method depends on the substrate material and the desired surface characteristics. For instance, plasma treatment offers a more controlled and environmentally friendly approach compared to chemical etching, which can generate hazardous waste. Careful control over parameters like plasma power, treatment time, and gas composition is crucial for achieving optimal surface activation without damaging the substrate.

Plating Solution and Process Parameters

The composition of the plating solution plays a vital role in determining the quality of the plated layer. Factors such as metal concentration, pH, temperature, and additives significantly impact the plating rate, morphology, and stress of the deposited metal. Optimizing these parameters is crucial to achieving a uniform and defect-free plating layer on the flexible substrate. For instance, higher temperatures generally result in faster plating rates but may also lead to increased roughness or porosity. Careful experimentation and process monitoring are necessary to find the optimal balance.

The plating process itself must be carefully controlled. Parameters such as current density, plating time, and agitation all affect the uniformity and thickness of the plating. Non-uniform current distribution on flexible substrates is a common challenge. Techniques like pulse plating or rotating the substrate during plating can help mitigate this issue by ensuring more even current distribution across the edge. Sophisticated plating equipment incorporating automated control systems allows for precise adjustment and monitoring of these parameters, improving repeatability and reducing variability.

Masking and Edge Definition

Precise control over the plated area is essential in flexible edge plating. Masking techniques are employed to restrict plating to the desired edge regions. Various masking materials, such as tapes, films, or stencils, can be used, each with its own advantages and limitations. The selection of the masking material should consider factors like adhesion to the substrate, chemical resistance to the plating solution, and ease of removal without damaging the substrate or the plated layer. Accurate masking is particularly challenging with complex edge geometries requiring meticulous attention to detail.

Advanced masking techniques, such as laser ablation or inkjet printing, offer greater precision and flexibility in defining the plated edge. Laser ablation can create highly accurate patterns, while inkjet printing allows for the creation of intricate designs and variable plating thicknesses along the edge. These techniques, however, require specialized equipment and expertise. The choice of masking technique should be based on the complexity of the edge geometry, the required plating precision, and the available resources.

Quality Control and Inspection

Rigorous quality control is essential to ensure the consistency and reliability of the flexible edge plating process. Various inspection methods are employed to assess the quality of the plated layer. Visual inspection can reveal gross defects such as cracks, voids, or delamination. Microscopic examination provides a more detailed analysis of surface morphology, thickness uniformity, and adhesion. Techniques such as cross-sectional microscopy can be used to accurately measure the thickness of the plated layer and to identify any interfacial defects.

Electrochemical techniques, such as electrochemical impedance spectroscopy (EIS) and cyclic voltammetry, can provide valuable information about the corrosion resistance and adhesion of the plated layer. These techniques are particularly useful for evaluating the long-term reliability of the plated components. Implementing a comprehensive quality control program, combining visual inspection, microscopy, and electrochemical techniques, is crucial for ensuring the high quality and consistent performance of the final products.

Conclusion

Optimizing flexible edge plating processes requires a multifaceted approach that encompasses substrate preparation, precise control over plating parameters, accurate masking techniques, and thorough quality control. By carefully considering each of these aspects and implementing appropriate strategies, manufacturers can achieve high-quality, consistent, and reliable flexible edge plating, meeting the demands of increasingly sophisticated electronic and other applications.

Enhanced Flexible Edge Plating Board Systems

Enhanced Flexibility and Design Freedom

The core advantage of these systems lies in their inherent flexibility. Unlike traditional rigid plating methods that restrict design to planar surfaces, enhanced flexible edge plating allows for the creation of PCBs that can be bent, folded, and conformed to various shapes. This opens up a vast array of design possibilities, enabling engineers to create more compact and aesthetically pleasing devices. The flexibility is achieved through the use of specialized flexible substrates, advanced plating techniques, and innovative design methodologies. This allows for the creation of circuits that can be seamlessly integrated into curved surfaces, such as the displays of wearable devices or the housings of automotive components.

Furthermore, the enhanced flexibility extends beyond the physical form factor. The design freedom offered allows for more complex routing and component placement, leading to more efficient circuit designs and improved overall performance. This freedom is particularly crucial in applications where space is at a premium, such as in mobile devices and medical implants. The ability to curve and conform the PCB allows for better integration with the surrounding components and a more streamlined overall design.

Improved Performance and Reliability

Beyond flexibility, Enhanced Flexible Edge Plating Board Systems boast improved electrical performance and reliability. The meticulous plating process ensures consistent and high-quality metallization, minimizing signal loss and impedance mismatches. This leads to improved signal integrity, crucial for high-speed data transmission and low-noise operation. The enhanced adhesion between the plating and the substrate further contributes to the overall reliability of the system, reducing the risk of delamination and other potential failure mechanisms.

Moreover, the flexibility of the system itself can contribute to enhanced reliability. In applications subject to vibration or bending stress, flexible PCBs are less prone to cracking or fracturing compared to their rigid counterparts. This characteristic makes them particularly suitable for applications in harsh environments or those involving significant mechanical stress.

Enhanced Manufacturability and Cost-Effectiveness

Despite the advanced technology involved, Enhanced Flexible Edge Plating Board Systems are designed for efficient and cost-effective manufacturing. While the initial investment in specialized equipment might be higher, the improved yield and reduced rework significantly offset these costs over time. The streamlined plating process reduces the number of processing steps, leading to faster production cycles and lower overall manufacturing costs.

Furthermore, the enhanced flexibility simplifies assembly processes. The ability to conform the PCB to complex shapes eliminates the need for laborious and time-consuming adjustments during the assembly phase. This streamlined process contributes to improved productivity and reduced labor costs, further enhancing the overall cost-effectiveness of these systems.

Applications and Future Trends

The applications of Enhanced Flexible Edge Plating Board Systems are vast and rapidly expanding. From wearable electronics and medical implants to automotive components and aerospace applications, these systems are revolutionizing the design and manufacturing of electronic devices. Their unique combination of flexibility, performance, and manufacturability makes them ideal for applications requiring intricate designs, compact form factors, and high reliability.

Looking towards the future, ongoing research and development are focused on further improving the flexibility, performance, and cost-effectiveness of these systems. The exploration of new materials, advanced plating techniques, and innovative design methodologies will continue to push the boundaries of what's possible in electronic packaging, leading to even more sophisticated and versatile applications in the years to come. The integration with other advanced technologies, such as flexible displays and sensors, will further enhance the capabilities and applicability of Enhanced Flexible Edge Plating Board Systems, shaping the future of electronics as we know it.

REPORT