-

Agriculture

Agriculture

-

Health-Care

Health-Care

-

Environment

Environment

-

Construction-Real-Estate

Construction-Real-Estate

-

Tools-Hardware

Tools-Hardware

-

Home-Garden

Home-Garden

-

Furniture

Furniture

-

Luggage-Bags-Cases

Luggage-Bags-Cases

-

Medical-devices-Supplies

Medical-devices-Supplies

-

Gifts-Crafts

Gifts-Crafts

-

Sports-Entertainment

Sports-Entertainment

-

Food-Beverage

Food-Beverage

-

Vehicles-Transportation

Vehicles-Transportation

-

Power-Transmission

Power-Transmission

-

Material-Handling

Material-Handling

-

Renewable-Energy

Renewable-Energy

-

Safety

Safety

-

Testing-Instrument-Equipment

Testing-Instrument-Equipment

-

Construction-Building-Machinery

Construction-Building-Machinery

-

Pet-Supplies

Pet-Supplies

-

Personal-Care-Household-Cleaning

Personal-Care-Household-Cleaning

-

Vehicle-Accessories-Electronics-Tools

Vehicle-Accessories-Electronics-Tools

-

School-Office-Supplies

School-Office-Supplies

-

Packaging-Printing

Packaging-Printing

-

Mother-Kids-Toys

Mother-Kids-Toys

-

Business-Services

Business-Services

-

Commercial-Equipment-Machinery

Commercial-Equipment-Machinery

-

Apparel-Accessories

Apparel-Accessories

-

Security

Security

-

Shoes-Accessories

Shoes-Accessories

-

Vehicle-Parts-Accessories

Vehicle-Parts-Accessories

-

Jewelry-Eyewear-Watches-Accessories

Jewelry-Eyewear-Watches-Accessories

-

Lights-Lighting

Lights-Lighting

-

Fabric-Textile-Raw-Material

Fabric-Textile-Raw-Material

-

Fabrication-Services

Fabrication-Services

-

Industrial-Machinery

Industrial-Machinery

-

Consumer-Electronics

Consumer-Electronics

-

Electrical-Equipment-Supplies

Electrical-Equipment-Supplies

-

Electronic-Components-Accessories-Telecommunications

Electronic-Components-Accessories-Telecommunications

-

Home-Appliances

Home-Appliances

-

Beauty

Beauty

-

Chemicals

Chemicals

-

Rubber-Plastics

Rubber-Plastics

-

Metals-Alloys

Metals-Alloys

- Masonry Materials

- Curtain Walls & Accessories

- Earthwork Products

- Fireproofing Materials

- Heat Insulation Materials

- Plastic Building Materials

- Building Boards

- Soundproofing Materials

- Timber

- Waterproofing Materials

- Balustrades & Handrails

- Bathroom & Kitchen

- Flooring & Accessories

- Tiles & Accessories

- Door, Window & Accessories

- Fireplaces & Stoves

- Floor Heating Systems & Parts

- Stairs & Stair Parts

- Ceilings

- Elevators & Escalators

- Stone

- Countertops, Vanity Tops & Table Tops

- Mosaics

- Metal Building Materials

- Multifunctional Materials

- Ladders & Scaffoldings

- Mouldings

- Corner Guards

- Decorative Films

- Formwork

- Building & Industrial Glass

- Other Construction & Real Estate

- Wallpapers/Wall panels

- HVAC System & Parts

- Outdoor Facilities

- Prefabricated Buildings

- Festive & Party Supplies

- Bathroom Products

- Household Sundries

- Rain Gear

- Garden Supplies

- Household Cleaning Tools & Accessories

- Lighters & Smoking Accessories

- Home Storage & Organization

- Household Scales

- Smart Home Improvement

- Home Textiles

- Kitchenware

- Drinkware & Accessories

- Dinnerware, Coffee & Wine

- Home Decor

- Golf

- Fitness & Body Building

- Amusement Park Facilities

- Billiards, Board Game,Coin Operated Games

- Musical Instruments

- Outdoor Affordable Luxury Sports

- Camping & Hiking

- Fishing

- Sports Safety&Rehabilitation

- Ball Sports Equipments

- Water Sports

- Winter Sports

- Luxury Travel Equipments

- Sports Shoes, Bags & Accessories

- Cycling

- Other Sports & Entertainment Products

- Artificial Grass&Sports Flooring&Sports Court Equipment

- Scooters

- Food Ingredients

- Honey & Honey Products

- Snacks

- Nuts & Kernels

- Seafood

- Plant & Animal Oil

- Beverages

- Fruit & Vegetable Products

- Frog & Escargot

- Bean Products

- Egg Products

- Dairy Products

- Seasonings & Condiments

- Canned Food

- Instant Food

- Baked Goods

- Other Food & Beverage

- Meat & Poultry

- Confectionery

- Grain Products

- Feminie Care

- Hair Care & Styling

- Body Care

- Hands & Feet Care

- Hygiene Products

- Men's Grooming

- Laundry Cleaning Supplies

- Travel Size & Gift Sets

- Room Deodorizers

- Other Personal Care Products

- Pest Control Products

- Special Household Cleaning

- Floor Cleaning

- Kitchen & Bathroom Cleaning

- Oral Care

- Bath Supplies

- Yellow Pages

- Correction Supplies

- Office Binding Supplies

- Office Cutting Supplies

- Board Erasers

- Office Adhesives & Tapes

- Education Supplies

- Pencil Cases & Bags

- Notebooks & Writing Pads

- File Folder Accessories

- Calendars

- Writing Accessories

- Commercial Office Supplies

- Pencil Sharpeners

- Pens

- Letter Pad/Paper

- Paper Envelopes

- Desk Organizers

- Pencils

- Markers & Highlighters

- Filing Products

- Art Supplies

- Easels

- Badge Holder & Accessories

- Office Paper

- Printer Supplies

- Book Covers

- Other Office & School Supplies

- Stationery Set

- Boards

- Clipboards

- Stamps

- Drafting Supplies

- Stencils

- Electronic Dictionary

- Books

- Map

- Magazines

- Calculators

- Baby & Toddler Toys

- Educational Toys

- Classic Toys

- Dress Up & Pretend Play

- Toy Vehicle

- Stuffed Animals & Plush Toys

- Outdoor Toys & Structures

- Balloons & Accessories

- Baby Food

- Children's Clothing

- Baby Supplies & Products

- Maternity Clothes

- Kids Shoes

- Baby Care

- Novelty & Gag Toys

- Dolls & Accessories

- Puzzle & Games

- Blocks & Model Building Toys

- Toddler Clothing

- Baby Clothing

- Kids' Luggage & Bags

- Arts, Crafts & DIY Toys

- Action & Toy Figures

- Baby Appliances

- Hobbies & Models

- Remote Control Toys

- Promotional Toys

- Pregnancy & Maternity

- Hygiene Products

- Kid's Textile&Bedding

- Novelty & Special Use

- Toy Weapons

- Baby Gifts

- Baby Storage & Organization

- Auto Drive Systems

- ATV/UTV Parts & Accessories

- Marine Parts & Accessories

- Other Auto Parts

- Trailer Parts & Accessories

- Auto Transmission Systems

- Train Parts & Accessories

- Universal Parts

- Railway Parts & Accessories

- Auto Brake Systems

- Aviation Parts & Accessories

- Truck Parts & Accessories

- Auto Suspension Systems

- Auto Lighting Systems

- New Energy Vehicle Parts & Accessories

- Auto Steering Systems

- Wheels, Tires & Accessories

- Bus Parts & Accessories

- Auto Performance Parts

- Cooling System

- Go-Kart & Kart Racer Parts & Accessories

- Air Conditioning Systems

- Heavy Duty Vehicle Parts & Accessories

- Auto Electrical Systems

- Auto Body Systems

- Auto Engine Systems

- Container Parts & Accessories

- Motorcycle Parts & Accessories

- Refrigeration & Heat Exchange Equipment

- Machine Tool Equipment

- Food & Beverage Machinery

- Agricultural Machinery & Equipment

- Apparel & Textile Machinery

- Chemical Machinery

- Packaging Machines

- Paper Production Machinery

- Plastic & Rubber Processing Machinery

- Industrial Robots

- Electronic Products Machinery

- Metal & Metallurgy Machinery

- Woodworking Machinery

- Home Product Manufacturing Machinery

- Machinery Accessories

- Environmental Machinery

- Machinery Service

- Electrical Equipment Manufacturing Machinery

- Industrial Compressors & Parts

- Tobacco & Cigarette Machinery

- Production Line

- Used Industrial Machinery

- Electronics Production Machinery

- Other Machinery & Industrial Equipment

- Camera, Photo & Accessories

- Portable Audio, Video & Accessories

- Television, Home Audio, Video & Accessories

- Video Games & Accessories

- Mobile Phone & Accessories

- Electronic Publications

- Earphone & Headphone & Accessories

- Speakers & Accessories

- Smart Electronics

- TV Receivers & Accessories

- Mobile Phone & Computer Repair Parts

- Chargers, Batteries & Power Supplies

- Used Electronics

- VR, AR, MR Hardware & Software

- Projectors & Presentation Equipments

- Other Consumer Electronics

- Cables & Commonly Used Accessories

- Computer Hardware & Software

- Displays, Signage and Optoelectronics

- Discrete Semiconductors

- Wireless & IoT Module and Products

- Telecommunications

- Connectors, Terminals & Accessories

- Development Boards, Electronic Modules and Kits

- Circuit Protection

- Sensors

- Isolators

- Audio Components and Products

- Integrated Circuits

- Power Supplies

- Relays

- RF, Microwave and RFID

- Electronic Accessories & Supplies

- Passive Components

- PCB & PCBA

- Air Quality Appliances

- Home Appliance Parts

- Heating & Cooling Appliances

- Small Kitchen Appliances

- Laundry Appliances

- Water Heaters

- Water Treatment Appliances

- Refrigerators & Freezers

- Personal Care & Beauty Appliances

- Major Kitchen Appliances

- Cleaning Appliances

- Second-hand Appliances

- Smart Home Appliances

- Other Home Appliances

- Energy Chemicals

- Inorganic Chemicals

- Basic Organic Chemicals

- Agrochemicals

- Admixture & Additives

- Catalysts & Chemical Auxiliary Agents

- Pigments & Dyestuff

- Coating & Paint

- Daily Chemicals

- Polymer

- Organic Intermediate

- Adhesives & Sealants

- Chemical Waste

- Biological Chemical Products

- Surface Treatment Chemicals

- Painting & Coating

- Chemical Reagents

- Flavor & Fragrance

- Non-Explosive Demolition Agents

- Other Chemicals

- Custom Chemical Services

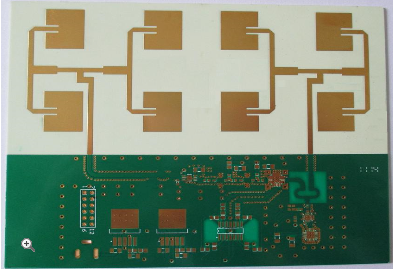

Advanced Materials And Fabrication Methods For High Frequency PCBs Supporting Microwave RF Applications And High Performance Computing

In the rapidly evolving landscape of modern electronics, the relentless push for higher data rates, greater bandwidth, and enhanced computational power has placed unprecedented demands on the fundamental building blocks of electronic systems. At the heart of cutting-edge technologies like 5G/6G communication networks, satellite systems, radar, and high-performance computing (HPC) servers lies a critical, yet often overlooked, component: the printed circuit board (PCB). Traditional PCB materials and manufacturing techniques, designed for lower-frequency digital applications, falter under the stringent requirements of microwave, RF, and high-speed digital signals. This has catalyzed a paradigm shift towards advanced materials and sophisticated fabrication methods specifically engineered for high-frequency PCBs. These specialized boards are not merely carriers of components; they are active, performance-defining elements that ensure signal integrity, minimize loss, and manage thermal and mechanical stresses in the most demanding environments. Understanding this technological frontier is essential for engineers and innovators aiming to unlock the next generation of electronic capabilities.

Advanced Dielectric Materials: The Foundation of Performance

The core of any high-frequency PCB is its dielectric substrate, the insulating material that separates the conductive copper layers. For microwave and RF applications, the choice of dielectric is paramount, as it directly influences signal propagation speed, loss, and stability. Traditional materials like FR-4, with their relatively high and inconsistent dielectric constant (Dk) and dissipation factor (Df), introduce significant signal attenuation and phase distortion at gigahertz frequencies. To overcome these limitations, advanced polymer composites and ceramic-filled PTFE (Polytetrafluoroethylene) materials have become industry standards.

Materials such as Rogers RO4000® series, Isola's Astra® MT77, and Taconic's RF-35 ceramic-PTFE blends offer exceptionally low and stable Dk values, often tailored to specific frequencies. Their ultra-low Df ensures minimal dielectric loss, preserving signal strength over distance. Furthermore, these materials exhibit excellent thermal stability, meaning their electrical properties remain consistent across a wide temperature range—a critical factor for outdoor or high-power applications. For HPC applications, where signal integrity for multi-gigabit serial links is crucial, low-loss laminates with tightly controlled dielectric constant tolerance are essential to maintain impedance control and reduce bit-error rates. The development of these engineered dielectrics represents a fundamental leap from commodity materials to application-specific solutions.

Precision Fabrication and Fine-Line Structuring

Advanced materials alone are insufficient without equally advanced fabrication techniques to realize their potential. The fabrication of high-frequency PCBs demands micron-level precision to achieve the controlled impedance, minimal signal skew, and reduced crosstalk required for high-speed operation. A cornerstone of this process is sophisticated etching technology. While standard PCBs might use subtractive etching, high-frequency designs increasingly rely on modified semi-additive processes (mSAP) and advanced laser direct imaging (LDI).

These methods allow for the creation of extremely fine traces and spaces, often down to 25 microns or less, with near-vertical sidewalls. This precision is vital for maintaining consistent trace geometry, which directly dictates the characteristic impedance (e.g., 50 or 100 ohms). Any variation in trace width or thickness can cause impedance discontinuities, leading to signal reflections and degradation. Additionally, the surface roughness of the copper foil is meticulously controlled. Smoother copper, achieved through treatments like reverse-treated foil (RTF) or very-low-profile (VLP) foil, reduces conductor loss at high frequencies by minimizing the skin effect, where current flows only on the conductor's surface. The interplay between material properties and fabrication precision defines the electrical performance envelope of the final PCB.

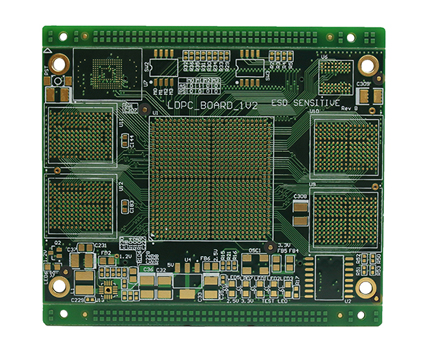

Multilayer Architecture and Via Technology

High-frequency and HPC systems are inherently complex, requiring dense component integration and multi-gigabit interconnects between layers. This necessitates sophisticated multilayer stack-ups and advanced via structures. The stack-up design is a careful balancing act, arranging signal, ground, and power planes to provide clear return paths, manage electromagnetic interference (EMI), and control cross-talk. Mixed dielectric stack-ups, combining different low-loss materials for optimal electrical and cost performance, are common.

Via technology is particularly critical. Standard through-hole vias act as impedance discontinuities and parasitic stubs at microwave frequencies, causing severe signal reflection and resonance. To mitigate this, a suite of specialized via structures is employed. Blind and buried vias connect only specific layers, eliminating unnecessary stubs. For the most critical high-speed differential pairs, coaxial-like structures such as grounded coplanar waveguides or back-drilled vias (stub removal) are used. The most advanced solution is the use of microvias—laser-drilled holes with diameters less than 150 microns—enabling high-density interconnect (HDI) architectures. These microvias facilitate the routing escape of fine-pitch ball grid array (BGA) packages found in FPGAs and processors for HPC, ensuring reliable connections while minimizing parasitic inductance and capacitance.

Surface Finishes and Thermal Management

The final surface finish of a PCB and its ability to manage heat are crucial for both reliability and high-frequency performance. The choice of surface finish affects solderability, shelf life, and, importantly, signal loss at high frequencies. Traditional finishes like Hot Air Solder Leveling (HASL) create an uneven surface, harming impedance control. Electroless Nickel Immersion Gold (ENIG) provides a flat, solderable surface but can introduce slight RF loss due to the nickel layer's magnetic properties.

For the most demanding RF applications, immersion silver or electroless palladium immersion gold (EPIG) are preferred for their excellent surface planarity and lower loss characteristics. Simultaneously, thermal management is a non-negotiable aspect of HPC and high-power RF designs. Advanced PCBs integrate thermal vias—arrays of copper-plated holes—under heat-generating components like power amplifiers or CPUs to conduct heat directly to internal ground planes or dedicated metal-core backers. In extreme cases, the PCB itself may be built on a metal core (e.g., aluminum) or use thermally conductive but electrically insulating dielectric materials to act as a heat spreader, ensuring component reliability and preventing performance throttling due to overheating.

Simulation, Testing, and The Path Forward

The design and validation of high-frequency PCBs are inseparable from advanced electromagnetic (EM) simulation tools. Before a single board is fabricated, engineers use 3D full-wave simulators like ANSYS HFSS or CST Studio Suite to model the entire structure—traces, vias, planes, and dielectric layers—predicting S-parameters (scattering parameters), impedance, and potential EMI issues. This virtual prototyping is essential due to the high cost of advanced materials and the complexity of fabrication; it allows for optimization and problem-solving in the design phase.

Post-fabrication, rigorous testing validates performance. Time-domain reflectometry (TDR) measures impedance profiles along traces, while vector network analyzers (VNAs) characterize S-parameters across the operational frequency band, quantifying insertion loss and return loss. The future of this field points towards further material innovation, such as liquid crystal polymer (LCP) substrates for ultra-flexible, high-frequency applications, and the integration of additive manufacturing techniques for creating unique embedded passives or waveguide structures. As the frontiers of frequency and computational speed continue to expand, the symbiotic advancement of materials science and fabrication artistry in high-frequency PCBs will remain the silent enabler of our connected, data-driven world.

REPORT