-

Agriculture

Agriculture

-

Health-Care

Health-Care

-

Environment

Environment

-

Construction-Real-Estate

Construction-Real-Estate

-

Tools-Hardware

Tools-Hardware

-

Home-Garden

Home-Garden

-

Furniture

Furniture

-

Luggage-Bags-Cases

Luggage-Bags-Cases

-

Medical-devices-Supplies

Medical-devices-Supplies

-

Gifts-Crafts

Gifts-Crafts

-

Sports-Entertainment

Sports-Entertainment

-

Food-Beverage

Food-Beverage

-

Vehicles-Transportation

Vehicles-Transportation

-

Power-Transmission

Power-Transmission

-

Material-Handling

Material-Handling

-

Renewable-Energy

Renewable-Energy

-

Safety

Safety

-

Testing-Instrument-Equipment

Testing-Instrument-Equipment

-

Construction-Building-Machinery

Construction-Building-Machinery

-

Pet-Supplies

Pet-Supplies

-

Personal-Care-Household-Cleaning

Personal-Care-Household-Cleaning

-

Vehicle-Accessories-Electronics-Tools

Vehicle-Accessories-Electronics-Tools

-

School-Office-Supplies

School-Office-Supplies

-

Packaging-Printing

Packaging-Printing

-

Mother-Kids-Toys

Mother-Kids-Toys

-

Business-Services

Business-Services

-

Commercial-Equipment-Machinery

Commercial-Equipment-Machinery

-

Apparel-Accessories

Apparel-Accessories

-

Security

Security

-

Shoes-Accessories

Shoes-Accessories

-

Vehicle-Parts-Accessories

Vehicle-Parts-Accessories

-

Jewelry-Eyewear-Watches-Accessories

Jewelry-Eyewear-Watches-Accessories

-

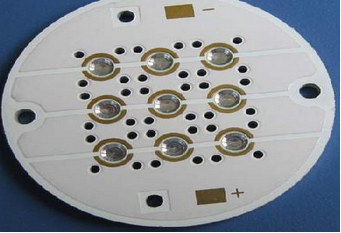

Lights-Lighting

Lights-Lighting

-

Fabric-Textile-Raw-Material

Fabric-Textile-Raw-Material

-

Fabrication-Services

Fabrication-Services

-

Industrial-Machinery

Industrial-Machinery

-

Consumer-Electronics

Consumer-Electronics

-

Electrical-Equipment-Supplies

Electrical-Equipment-Supplies

-

Electronic-Components-Accessories-Telecommunications

Electronic-Components-Accessories-Telecommunications

-

Home-Appliances

Home-Appliances

-

Beauty

Beauty

-

Chemicals

Chemicals

-

Rubber-Plastics

Rubber-Plastics

-

Metals-Alloys

Metals-Alloys

- Masonry Materials

- Curtain Walls & Accessories

- Earthwork Products

- Fireproofing Materials

- Heat Insulation Materials

- Plastic Building Materials

- Building Boards

- Soundproofing Materials

- Timber

- Waterproofing Materials

- Balustrades & Handrails

- Bathroom & Kitchen

- Flooring & Accessories

- Tiles & Accessories

- Door, Window & Accessories

- Fireplaces & Stoves

- Floor Heating Systems & Parts

- Stairs & Stair Parts

- Ceilings

- Elevators & Escalators

- Stone

- Countertops, Vanity Tops & Table Tops

- Mosaics

- Metal Building Materials

- Multifunctional Materials

- Ladders & Scaffoldings

- Mouldings

- Corner Guards

- Decorative Films

- Formwork

- Building & Industrial Glass

- Other Construction & Real Estate

- Wallpapers/Wall panels

- HVAC System & Parts

- Outdoor Facilities

- Prefabricated Buildings

- Festive & Party Supplies

- Bathroom Products

- Household Sundries

- Rain Gear

- Garden Supplies

- Household Cleaning Tools & Accessories

- Lighters & Smoking Accessories

- Home Storage & Organization

- Household Scales

- Smart Home Improvement

- Home Textiles

- Kitchenware

- Drinkware & Accessories

- Dinnerware, Coffee & Wine

- Home Decor

- Golf

- Fitness & Body Building

- Amusement Park Facilities

- Billiards, Board Game,Coin Operated Games

- Musical Instruments

- Outdoor Affordable Luxury Sports

- Camping & Hiking

- Fishing

- Sports Safety&Rehabilitation

- Ball Sports Equipments

- Water Sports

- Winter Sports

- Luxury Travel Equipments

- Sports Shoes, Bags & Accessories

- Cycling

- Other Sports & Entertainment Products

- Artificial Grass&Sports Flooring&Sports Court Equipment

- Scooters

- Food Ingredients

- Honey & Honey Products

- Snacks

- Nuts & Kernels

- Seafood

- Plant & Animal Oil

- Beverages

- Fruit & Vegetable Products

- Frog & Escargot

- Bean Products

- Egg Products

- Dairy Products

- Seasonings & Condiments

- Canned Food

- Instant Food

- Baked Goods

- Other Food & Beverage

- Meat & Poultry

- Confectionery

- Grain Products

- Feminie Care

- Hair Care & Styling

- Body Care

- Hands & Feet Care

- Hygiene Products

- Men's Grooming

- Laundry Cleaning Supplies

- Travel Size & Gift Sets

- Room Deodorizers

- Other Personal Care Products

- Pest Control Products

- Special Household Cleaning

- Floor Cleaning

- Kitchen & Bathroom Cleaning

- Oral Care

- Bath Supplies

- Yellow Pages

- Correction Supplies

- Office Binding Supplies

- Office Cutting Supplies

- Board Erasers

- Office Adhesives & Tapes

- Education Supplies

- Pencil Cases & Bags

- Notebooks & Writing Pads

- File Folder Accessories

- Calendars

- Writing Accessories

- Commercial Office Supplies

- Pencil Sharpeners

- Pens

- Letter Pad/Paper

- Paper Envelopes

- Desk Organizers

- Pencils

- Markers & Highlighters

- Filing Products

- Art Supplies

- Easels

- Badge Holder & Accessories

- Office Paper

- Printer Supplies

- Book Covers

- Other Office & School Supplies

- Stationery Set

- Boards

- Clipboards

- Stamps

- Drafting Supplies

- Stencils

- Electronic Dictionary

- Books

- Map

- Magazines

- Calculators

- Baby & Toddler Toys

- Educational Toys

- Classic Toys

- Dress Up & Pretend Play

- Toy Vehicle

- Stuffed Animals & Plush Toys

- Outdoor Toys & Structures

- Balloons & Accessories

- Baby Food

- Children's Clothing

- Baby Supplies & Products

- Maternity Clothes

- Kids Shoes

- Baby Care

- Novelty & Gag Toys

- Dolls & Accessories

- Puzzle & Games

- Blocks & Model Building Toys

- Toddler Clothing

- Baby Clothing

- Kids' Luggage & Bags

- Arts, Crafts & DIY Toys

- Action & Toy Figures

- Baby Appliances

- Hobbies & Models

- Remote Control Toys

- Promotional Toys

- Pregnancy & Maternity

- Hygiene Products

- Kid's Textile&Bedding

- Novelty & Special Use

- Toy Weapons

- Baby Gifts

- Baby Storage & Organization

- Auto Drive Systems

- ATV/UTV Parts & Accessories

- Marine Parts & Accessories

- Other Auto Parts

- Trailer Parts & Accessories

- Auto Transmission Systems

- Train Parts & Accessories

- Universal Parts

- Railway Parts & Accessories

- Auto Brake Systems

- Aviation Parts & Accessories

- Truck Parts & Accessories

- Auto Suspension Systems

- Auto Lighting Systems

- New Energy Vehicle Parts & Accessories

- Auto Steering Systems

- Wheels, Tires & Accessories

- Bus Parts & Accessories

- Auto Performance Parts

- Cooling System

- Go-Kart & Kart Racer Parts & Accessories

- Air Conditioning Systems

- Heavy Duty Vehicle Parts & Accessories

- Auto Electrical Systems

- Auto Body Systems

- Auto Engine Systems

- Container Parts & Accessories

- Motorcycle Parts & Accessories

- Refrigeration & Heat Exchange Equipment

- Machine Tool Equipment

- Food & Beverage Machinery

- Agricultural Machinery & Equipment

- Apparel & Textile Machinery

- Chemical Machinery

- Packaging Machines

- Paper Production Machinery

- Plastic & Rubber Processing Machinery

- Industrial Robots

- Electronic Products Machinery

- Metal & Metallurgy Machinery

- Woodworking Machinery

- Home Product Manufacturing Machinery

- Machinery Accessories

- Environmental Machinery

- Machinery Service

- Electrical Equipment Manufacturing Machinery

- Industrial Compressors & Parts

- Tobacco & Cigarette Machinery

- Production Line

- Used Industrial Machinery

- Electronics Production Machinery

- Other Machinery & Industrial Equipment

- Camera, Photo & Accessories

- Portable Audio, Video & Accessories

- Television, Home Audio, Video & Accessories

- Video Games & Accessories

- Mobile Phone & Accessories

- Electronic Publications

- Earphone & Headphone & Accessories

- Speakers & Accessories

- Smart Electronics

- TV Receivers & Accessories

- Mobile Phone & Computer Repair Parts

- Chargers, Batteries & Power Supplies

- Used Electronics

- VR, AR, MR Hardware & Software

- Projectors & Presentation Equipments

- Other Consumer Electronics

- Cables & Commonly Used Accessories

- Computer Hardware & Software

- Displays, Signage and Optoelectronics

- Discrete Semiconductors

- Wireless & IoT Module and Products

- Telecommunications

- Connectors, Terminals & Accessories

- Development Boards, Electronic Modules and Kits

- Circuit Protection

- Sensors

- Isolators

- Audio Components and Products

- Integrated Circuits

- Power Supplies

- Relays

- RF, Microwave and RFID

- Electronic Accessories & Supplies

- Passive Components

- PCB & PCBA

- Air Quality Appliances

- Home Appliance Parts

- Heating & Cooling Appliances

- Small Kitchen Appliances

- Laundry Appliances

- Water Heaters

- Water Treatment Appliances

- Refrigerators & Freezers

- Personal Care & Beauty Appliances

- Major Kitchen Appliances

- Cleaning Appliances

- Second-hand Appliances

- Smart Home Appliances

- Other Home Appliances

- Energy Chemicals

- Inorganic Chemicals

- Basic Organic Chemicals

- Agrochemicals

- Admixture & Additives

- Catalysts & Chemical Auxiliary Agents

- Pigments & Dyestuff

- Coating & Paint

- Daily Chemicals

- Polymer

- Organic Intermediate

- Adhesives & Sealants

- Chemical Waste

- Biological Chemical Products

- Surface Treatment Chemicals

- Painting & Coating

- Chemical Reagents

- Flavor & Fragrance

- Non-Explosive Demolition Agents

- Other Chemicals

- Custom Chemical Services

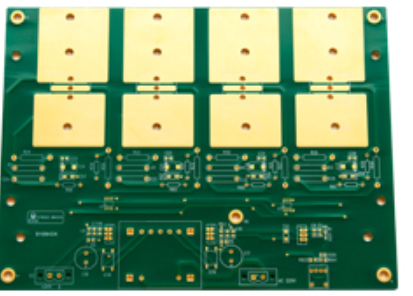

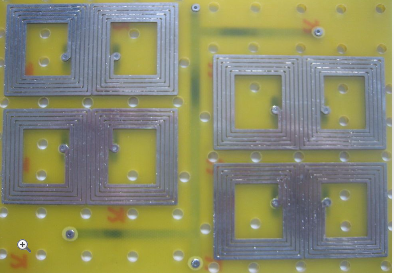

Cutting Edge PCB Technology For Miniaturized Filters And High Power Amplifiers In Compact Devices

In an era defined by the relentless pursuit of smaller, smarter, and more powerful electronic devices, the role of printed circuit board (PCB) technology has evolved from a passive substrate to a critical, performance-defining component. The challenge of integrating sophisticated functionalities like precise radio frequency (RF) filtering and high-power amplification into shrinking form factors—from advanced smartphones and wearable medical monitors to compact satellite communication modules—pushes conventional PCB materials and designs to their limits. This article delves into the cutting-edge PCB technologies that are making the impossible possible: enabling miniaturized filters and high-power amplifiers to coexist and perform reliably within the tight confines of modern compact devices. By exploring innovations in materials science, novel design methodologies, and advanced manufacturing techniques, we uncover how these foundational advancements are driving the next wave of electronic miniaturization and power density, setting the stage for a new generation of ultra-compact, high-performance systems.

Advanced Materials for Enhanced Electrical and Thermal Performance

The foundation of any high-performance PCB lies in its substrate material. Traditional materials like FR-4 are often inadequate for RF and high-power applications due to their relatively high dielectric loss and poor thermal conductivity. Cutting-edge devices now leverage specialized laminates. For high-frequency filters, materials with a low and stable dielectric constant (Dk) and a very low dissipation factor (Df) are paramount. Laminates based on polytetrafluoroethylene (PTFE), ceramic-filled hydrocarbons, or liquid crystal polymer (LCP) provide excellent signal integrity at microwave frequencies, allowing for the design of miniaturized filters with sharp roll-off and minimal insertion loss. These materials ensure that filter performance remains consistent despite environmental changes.

For high-power amplifiers, thermal management becomes the primary concern. Amplifiers generate significant heat, which, if not dissipated efficiently, degrades performance and reliability. Advanced PCB technologies incorporate metal-core substrates, insulated metal substrates (IMS), or substrates with high thermal conductivity ceramics (e.g., aluminum nitride). These materials act as heat spreaders, rapidly conducting heat away from active components like GaN or GaAs transistors to the device housing or heat sinks. Furthermore, the use of thermally conductive but electrically insulating dielectric layers within these substrates prevents short circuits while optimizing heat transfer, enabling amplifiers to operate at higher power levels in a compact space without thermal throttling.

Innovative Design and Integration Techniques

Beyond materials, revolutionary design approaches are crucial for miniaturization. For filters, traditional lumped-element components (discrete inductors and capacitors) consume excessive board space. The cutting-edge solution is the use of embedded passive components and distributed element designs. Using the PCB layers themselves, designers can create planar filter structures like microstrip, stripline, or cavity-based filters. Techniques like Low Temperature Co-fired Ceramic (LTCC) or multilayer organic laminates allow these complex three-dimensional filter structures to be buried within the PCB stack-up, freeing up valuable surface real estate for other components and drastically reducing the overall footprint.

Integration reaches its zenith with System-in-Package (SiP) and advanced embedded component technologies. Here, the PCB transforms into a heterogeneous integration platform. Bare die amplifiers, filter chips, and other ICs can be mounted directly onto substrates using flip-chip or wafer-level packaging techniques, interconnected by high-density fan-out traces or through-silicon vias (TSVs). This approach minimizes parasitic inductances and capacitances that plague traditional wire-bonding, which is vital for both filter sharpness and amplifier efficiency. By vertically stacking and embedding functionalities, the PCB becomes a compact, multi-functional module that houses the entire RF front-end, pushing the boundaries of what constitutes a "circuit board."

Precision Manufacturing and Interconnect Solutions

The realization of these sophisticated designs demands equally advanced manufacturing capabilities. Fine-line patterning and high-density interconnect (HDI) technology are essential. Using processes like semi-additive processing (mSAP), manufacturers can create trace widths and spacings as low as 15-20 micrometers. This precision is critical for designing the intricate geometries of miniaturized planar filters operating at high frequencies, where trace dimensions directly determine electrical characteristics. HDI, with its microvias and multiple sequential lamination cycles, enables the complex routing required for dense, multi-layer embedded designs, ensuring reliable connections in a minuscule area.

For high-power sections, the quality of interconnects and power planes is non-negotiable. Heavy copper cladding (up to several ounces) is used to carry high currents without overheating. Advanced plating techniques ensure robust via walls, which are crucial for delivering power to amplifiers and for thermal vias that conduct heat to lower layers or metal cores. Furthermore, the interface between the PCB and high-power components is optimized using materials with matched coefficients of thermal expansion (CTE) to prevent solder joint fatigue and delamination during power cycling. This manufacturing precision ensures that the miniaturized system does not compromise on durability or electrical robustness.

Simulation-Driven Design and Future Trajectories

The complexity of integrating sensitive filters and powerful amplifiers in proximity necessitates a paradigm shift in design methodology. Electromagnetic (EM) and thermal simulation tools are now indispensable from the earliest stages. Engineers use 3D full-wave EM simulators to model the entire PCB layout, predicting parasitic couplings between the filter and amplifier sections, ground plane effects, and radiation losses. This allows for pre-emptive optimization, ensuring that the amplifier's output does not interfere with the filter's passband and that isolation is maintained.

Looking forward, the convergence of these technologies points toward even greater integration. Research into additive manufacturing (3D printing) of PCBs promises unprecedented design freedom for creating optimal, non-planar RF structures. The use of artificial intelligence in design software can automate the optimization of layout for performance, size, and thermal management. As the Internet of Things (IoT) and 5G/6G technologies demand more from compact devices, cutting-edge PCB technology will continue to be the silent enabler, seamlessly merging the worlds of precise signal conditioning and raw power amplification onto a single, remarkably sophisticated platform.

REPORT