-

Agriculture

Agriculture

-

Health-Care

Health-Care

-

Environment

Environment

-

Construction-Real-Estate

Construction-Real-Estate

-

Tools-Hardware

Tools-Hardware

-

Home-Garden

Home-Garden

-

Furniture

Furniture

-

Luggage-Bags-Cases

Luggage-Bags-Cases

-

Medical-devices-Supplies

Medical-devices-Supplies

-

Gifts-Crafts

Gifts-Crafts

-

Sports-Entertainment

Sports-Entertainment

-

Food-Beverage

Food-Beverage

-

Vehicles-Transportation

Vehicles-Transportation

-

Power-Transmission

Power-Transmission

-

Material-Handling

Material-Handling

-

Renewable-Energy

Renewable-Energy

-

Safety

Safety

-

Testing-Instrument-Equipment

Testing-Instrument-Equipment

-

Construction-Building-Machinery

Construction-Building-Machinery

-

Pet-Supplies

Pet-Supplies

-

Personal-Care-Household-Cleaning

Personal-Care-Household-Cleaning

-

Vehicle-Accessories-Electronics-Tools

Vehicle-Accessories-Electronics-Tools

-

School-Office-Supplies

School-Office-Supplies

-

Packaging-Printing

Packaging-Printing

-

Mother-Kids-Toys

Mother-Kids-Toys

-

Business-Services

Business-Services

-

Commercial-Equipment-Machinery

Commercial-Equipment-Machinery

-

Apparel-Accessories

Apparel-Accessories

-

Security

Security

-

Shoes-Accessories

Shoes-Accessories

-

Vehicle-Parts-Accessories

Vehicle-Parts-Accessories

-

Jewelry-Eyewear-Watches-Accessories

Jewelry-Eyewear-Watches-Accessories

-

Lights-Lighting

Lights-Lighting

-

Fabric-Textile-Raw-Material

Fabric-Textile-Raw-Material

-

Fabrication-Services

Fabrication-Services

-

Industrial-Machinery

Industrial-Machinery

-

Consumer-Electronics

Consumer-Electronics

-

Electrical-Equipment-Supplies

Electrical-Equipment-Supplies

-

Electronic-Components-Accessories-Telecommunications

Electronic-Components-Accessories-Telecommunications

-

Home-Appliances

Home-Appliances

-

Beauty

Beauty

-

Chemicals

Chemicals

-

Rubber-Plastics

Rubber-Plastics

-

Metals-Alloys

Metals-Alloys

- Masonry Materials

- Curtain Walls & Accessories

- Earthwork Products

- Fireproofing Materials

- Heat Insulation Materials

- Plastic Building Materials

- Building Boards

- Soundproofing Materials

- Timber

- Waterproofing Materials

- Balustrades & Handrails

- Bathroom & Kitchen

- Flooring & Accessories

- Tiles & Accessories

- Door, Window & Accessories

- Fireplaces & Stoves

- Floor Heating Systems & Parts

- Stairs & Stair Parts

- Ceilings

- Elevators & Escalators

- Stone

- Countertops, Vanity Tops & Table Tops

- Mosaics

- Metal Building Materials

- Multifunctional Materials

- Ladders & Scaffoldings

- Mouldings

- Corner Guards

- Decorative Films

- Formwork

- Building & Industrial Glass

- Other Construction & Real Estate

- Wallpapers/Wall panels

- HVAC System & Parts

- Outdoor Facilities

- Prefabricated Buildings

- Festive & Party Supplies

- Bathroom Products

- Household Sundries

- Rain Gear

- Garden Supplies

- Household Cleaning Tools & Accessories

- Lighters & Smoking Accessories

- Home Storage & Organization

- Household Scales

- Smart Home Improvement

- Home Textiles

- Kitchenware

- Drinkware & Accessories

- Dinnerware, Coffee & Wine

- Home Decor

- Golf

- Fitness & Body Building

- Amusement Park Facilities

- Billiards, Board Game,Coin Operated Games

- Musical Instruments

- Outdoor Affordable Luxury Sports

- Camping & Hiking

- Fishing

- Sports Safety&Rehabilitation

- Ball Sports Equipments

- Water Sports

- Winter Sports

- Luxury Travel Equipments

- Sports Shoes, Bags & Accessories

- Cycling

- Other Sports & Entertainment Products

- Artificial Grass&Sports Flooring&Sports Court Equipment

- Scooters

- Food Ingredients

- Honey & Honey Products

- Snacks

- Nuts & Kernels

- Seafood

- Plant & Animal Oil

- Beverages

- Fruit & Vegetable Products

- Frog & Escargot

- Bean Products

- Egg Products

- Dairy Products

- Seasonings & Condiments

- Canned Food

- Instant Food

- Baked Goods

- Other Food & Beverage

- Meat & Poultry

- Confectionery

- Grain Products

- Feminie Care

- Hair Care & Styling

- Body Care

- Hands & Feet Care

- Hygiene Products

- Men's Grooming

- Laundry Cleaning Supplies

- Travel Size & Gift Sets

- Room Deodorizers

- Other Personal Care Products

- Pest Control Products

- Special Household Cleaning

- Floor Cleaning

- Kitchen & Bathroom Cleaning

- Oral Care

- Bath Supplies

- Yellow Pages

- Correction Supplies

- Office Binding Supplies

- Office Cutting Supplies

- Board Erasers

- Office Adhesives & Tapes

- Education Supplies

- Pencil Cases & Bags

- Notebooks & Writing Pads

- File Folder Accessories

- Calendars

- Writing Accessories

- Commercial Office Supplies

- Pencil Sharpeners

- Pens

- Letter Pad/Paper

- Paper Envelopes

- Desk Organizers

- Pencils

- Markers & Highlighters

- Filing Products

- Art Supplies

- Easels

- Badge Holder & Accessories

- Office Paper

- Printer Supplies

- Book Covers

- Other Office & School Supplies

- Stationery Set

- Boards

- Clipboards

- Stamps

- Drafting Supplies

- Stencils

- Electronic Dictionary

- Books

- Map

- Magazines

- Calculators

- Baby & Toddler Toys

- Educational Toys

- Classic Toys

- Dress Up & Pretend Play

- Toy Vehicle

- Stuffed Animals & Plush Toys

- Outdoor Toys & Structures

- Balloons & Accessories

- Baby Food

- Children's Clothing

- Baby Supplies & Products

- Maternity Clothes

- Kids Shoes

- Baby Care

- Novelty & Gag Toys

- Dolls & Accessories

- Puzzle & Games

- Blocks & Model Building Toys

- Toddler Clothing

- Baby Clothing

- Kids' Luggage & Bags

- Arts, Crafts & DIY Toys

- Action & Toy Figures

- Baby Appliances

- Hobbies & Models

- Remote Control Toys

- Promotional Toys

- Pregnancy & Maternity

- Hygiene Products

- Kid's Textile&Bedding

- Novelty & Special Use

- Toy Weapons

- Baby Gifts

- Baby Storage & Organization

- Auto Drive Systems

- ATV/UTV Parts & Accessories

- Marine Parts & Accessories

- Other Auto Parts

- Trailer Parts & Accessories

- Auto Transmission Systems

- Train Parts & Accessories

- Universal Parts

- Railway Parts & Accessories

- Auto Brake Systems

- Aviation Parts & Accessories

- Truck Parts & Accessories

- Auto Suspension Systems

- Auto Lighting Systems

- New Energy Vehicle Parts & Accessories

- Auto Steering Systems

- Wheels, Tires & Accessories

- Bus Parts & Accessories

- Auto Performance Parts

- Cooling System

- Go-Kart & Kart Racer Parts & Accessories

- Air Conditioning Systems

- Heavy Duty Vehicle Parts & Accessories

- Auto Electrical Systems

- Auto Body Systems

- Auto Engine Systems

- Container Parts & Accessories

- Motorcycle Parts & Accessories

- Refrigeration & Heat Exchange Equipment

- Machine Tool Equipment

- Food & Beverage Machinery

- Agricultural Machinery & Equipment

- Apparel & Textile Machinery

- Chemical Machinery

- Packaging Machines

- Paper Production Machinery

- Plastic & Rubber Processing Machinery

- Industrial Robots

- Electronic Products Machinery

- Metal & Metallurgy Machinery

- Woodworking Machinery

- Home Product Manufacturing Machinery

- Machinery Accessories

- Environmental Machinery

- Machinery Service

- Electrical Equipment Manufacturing Machinery

- Industrial Compressors & Parts

- Tobacco & Cigarette Machinery

- Production Line

- Used Industrial Machinery

- Electronics Production Machinery

- Other Machinery & Industrial Equipment

- Camera, Photo & Accessories

- Portable Audio, Video & Accessories

- Television, Home Audio, Video & Accessories

- Video Games & Accessories

- Mobile Phone & Accessories

- Electronic Publications

- Earphone & Headphone & Accessories

- Speakers & Accessories

- Smart Electronics

- TV Receivers & Accessories

- Mobile Phone & Computer Repair Parts

- Chargers, Batteries & Power Supplies

- Used Electronics

- VR, AR, MR Hardware & Software

- Projectors & Presentation Equipments

- Other Consumer Electronics

- Cables & Commonly Used Accessories

- Computer Hardware & Software

- Displays, Signage and Optoelectronics

- Discrete Semiconductors

- Wireless & IoT Module and Products

- Telecommunications

- Connectors, Terminals & Accessories

- Development Boards, Electronic Modules and Kits

- Circuit Protection

- Sensors

- Isolators

- Audio Components and Products

- Integrated Circuits

- Power Supplies

- Relays

- RF, Microwave and RFID

- Electronic Accessories & Supplies

- Passive Components

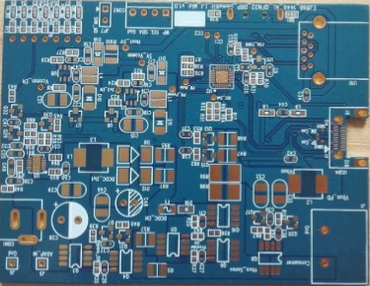

- PCB & PCBA

- Air Quality Appliances

- Home Appliance Parts

- Heating & Cooling Appliances

- Small Kitchen Appliances

- Laundry Appliances

- Water Heaters

- Water Treatment Appliances

- Refrigerators & Freezers

- Personal Care & Beauty Appliances

- Major Kitchen Appliances

- Cleaning Appliances

- Second-hand Appliances

- Smart Home Appliances

- Other Home Appliances

- Energy Chemicals

- Inorganic Chemicals

- Basic Organic Chemicals

- Agrochemicals

- Admixture & Additives

- Catalysts & Chemical Auxiliary Agents

- Pigments & Dyestuff

- Coating & Paint

- Daily Chemicals

- Polymer

- Organic Intermediate

- Adhesives & Sealants

- Chemical Waste

- Biological Chemical Products

- Surface Treatment Chemicals

- Painting & Coating

- Chemical Reagents

- Flavor & Fragrance

- Non-Explosive Demolition Agents

- Other Chemicals

- Custom Chemical Services

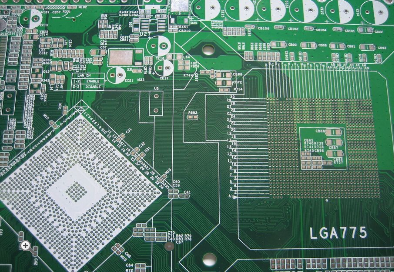

Impedance Considerations for Multilayer PCB Designs Managing Stackups and Materials to Maintain Signal Integrity Across Layers

In the rapidly advancing world of electronics, where signal speeds soar into the gigahertz range and device miniaturization continues unabated, the integrity of signals traveling across a printed circuit board (PCB) is paramount. At the heart of this challenge lies the critical concept of controlled impedance. For multilayer PCB designs, achieving and maintaining consistent impedance across different layers is not merely a best practice but a fundamental requirement for reliable high-speed digital and high-frequency analog performance. This article delves into the intricate considerations of impedance management in multilayer PCBs, focusing on how strategic stackup design and material selection form the bedrock of preserving signal integrity from layer to layer. As data rates increase and edge rates sharpen, reflections, crosstalk, and electromagnetic interference (EMI) can severely degrade system performance if impedance is not meticulously controlled. Understanding these principles is essential for engineers aiming to design robust, first-pass-success systems for applications ranging from telecommunications and computing to advanced automotive and aerospace electronics.

The Fundamental Role of PCB Stackup in Impedance Control

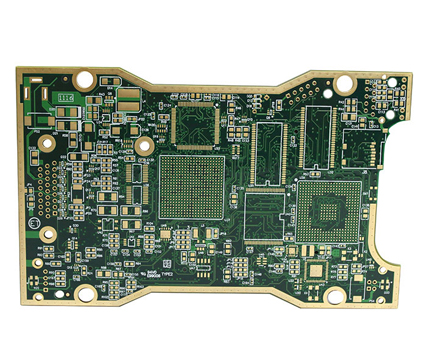

The stackup—the arrangement of copper and insulating dielectric layers in a PCB—is the primary blueprint for impedance control. A well-planned stackup provides a predictable electromagnetic environment for signals. It defines the physical dimensions, such as trace width and the distance to reference planes, which are direct inputs into impedance calculations. For multilayer boards, a symmetrical stackup around the center layer is often preferred, as it helps prevent warping during fabrication and provides a balanced distribution of power and ground planes, which is crucial for managing return currents.

Each signal layer should be adjacent to, or closely coupled with, a continuous reference plane (power or ground). This proximity creates a clear return path for high-frequency signals, minimizing loop inductance and containing electromagnetic fields. The separation distance between the signal trace and its reference plane, known as the dielectric height (H), is inversely related to the trace impedance for a given width. Therefore, precise control over this laminate thickness during the stackup specification is non-negotiable. Designers must work closely with PCB fabricators to select standard dielectric thicknesses that yield the target impedance with manufacturable trace widths.

Material Selection: Dielectric Constant and Loss Tangent

The choice of PCB substrate material profoundly impacts impedance stability and signal quality. The key parameters are the dielectric constant (Dk or εr) and the dissipation factor (Df), also known as loss tangent. The Dk value influences the propagation speed of the signal and the effective capacitance of the trace. A stable, consistent Dk across the board and across the operational frequency range is vital for maintaining uniform impedance. Variations in Dk can lead to impedance mismatches and timing skews.

For standard FR-4 materials, Dk can vary significantly with frequency and between material lots, which may be acceptable for lower-speed designs. However, for high-speed digital designs (e.g., PCIe, DDR, SerDes) or RF applications, advanced materials with tighter Dk tolerances, such as Rogers, Isola, or Nelco laminates, are often necessary. These materials offer not only stable Dk but also a lower loss tangent. The loss tangent represents the material's inherent signal energy absorption, converting it into heat. A lower Df is critical for minimizing insertion loss over long traces or at very high frequencies, ensuring signals arrive at their destination with sufficient strength and clarity.

Trace Geometry and Impedance Calculation

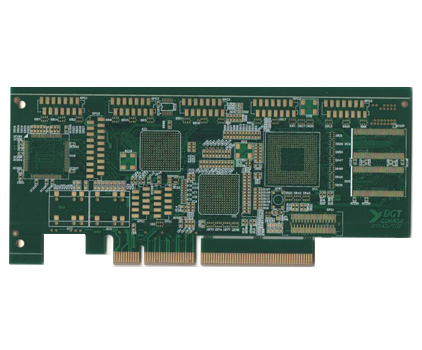

Once the stackup and materials are defined, the physical geometry of the trace becomes the adjustable variable to hit the target impedance. The primary dimensions are trace width (W), trace thickness (T), and the height to the reference plane (H). For common configurations like microstrip (outer layer) or stripline (inner layer), field solvers or industry-standard formulas (e.g., those from IPC-2141) are used to calculate the required width. It is important to note that fabricators will etch copper, causing traces to have a trapezoidal cross-section rather than a perfect rectangle; this effect must be accounted for in high-precision designs.

Differential pair routing introduces another layer of geometry control. Here, the impedance is determined not only by each trace's relationship to the reference plane but also by the coupling between the two traces of the pair. The key parameters become the trace width, the spacing (S) between the two traces, and the height to the plane. Tight coupling can help with noise immunity but makes the impedance more sensitive to manufacturing variations in spacing. The choice between edge-coupled and broadside-coupled stripline for inner layers further expands the geometric design space, each with its own advantages and fabrication considerations.

Manufacturing Tolerances and Their Impact

Even with a perfect theoretical design, real-world manufacturing variations will introduce impedance deviations. Key tolerances include copper thickness (±1 oz can vary), dielectric thickness (typically ±10%), trace width etching tolerance, and material Dk variation. A robust design must account for these by specifying impedance with an acceptable tolerance window (e.g., 50Ω ±10%). Performing a tolerance analysis using the worst-case variations in H, W, and Dk is essential to ensure the design remains functional under all manufacturing scenarios.

Collaboration with the PCB fabricator from the early design stages is critical. They can provide their specific process capabilities (e.g., minimum trace/space, controlled dielectric thicknesses) and often have preferred stackup configurations. Providing them with a complete stackup drawing, including target impedances for each critical signal layer, allows them to adjust their processes, such as controlling laminate prepreg resin content, to better achieve the desired results. They will also perform coupon testing on the production panel to verify impedance values before shipping.

Cross-Layer Transitions and Via Management

In a multilayer board, signals inevitably must change layers using vias. These vertical transitions are major sources of impedance discontinuity and signal integrity degradation. A via stub—the unused portion of a via barrel that extends beyond the signal transition layers—acts as a resonant antenna, causing significant reflections at high frequencies. Techniques like back-drilling to remove stubs or using blind/buried vias are employed to mitigate this effect.

The via structure itself introduces parasitic capacitance and inductance, creating a localized impedance drop. To manage this, the return current path must be maintained during the layer transition. This is achieved by placing return vias (ground vias) very close to the signal via, providing a short path for the return current to jump between reference planes. For critical high-speed signals, a return via for each reference plane layer is ideal. Furthermore, anti-pads—the clearance holes in unused copper planes around the via—must be sized appropriately; too small an anti-pad adds excessive parasitic capacitance, while too large can break the return path.

Successfully managing impedance in multilayer PCBs is a multidimensional engineering discipline that synthesizes stackup architecture, material science, geometric precision, and manufacturing pragmatism. It requires a proactive approach, where signal integrity is not an afterthought but a guiding principle from the initial design concept. By meticulously planning the layer stackup, selecting materials with appropriate electrical properties, calculating and optimizing trace geometries, accounting for fabrication tolerances, and carefully engineering layer transitions, designers can create multilayer PCBs that maintain impeccable signal integrity across all layers. This diligence ensures that the final product meets its performance specifications reliably, paving the way for the next generation of high-speed electronic systems.

REPORT