-

Agriculture

Agriculture

-

Health-Care

Health-Care

-

Environment

Environment

-

Construction-Real-Estate

Construction-Real-Estate

-

Tools-Hardware

Tools-Hardware

-

Home-Garden

Home-Garden

-

Furniture

Furniture

-

Luggage-Bags-Cases

Luggage-Bags-Cases

-

Medical-devices-Supplies

Medical-devices-Supplies

-

Gifts-Crafts

Gifts-Crafts

-

Sports-Entertainment

Sports-Entertainment

-

Food-Beverage

Food-Beverage

-

Vehicles-Transportation

Vehicles-Transportation

-

Power-Transmission

Power-Transmission

-

Material-Handling

Material-Handling

-

Renewable-Energy

Renewable-Energy

-

Safety

Safety

-

Testing-Instrument-Equipment

Testing-Instrument-Equipment

-

Construction-Building-Machinery

Construction-Building-Machinery

-

Pet-Supplies

Pet-Supplies

-

Personal-Care-Household-Cleaning

Personal-Care-Household-Cleaning

-

Vehicle-Accessories-Electronics-Tools

Vehicle-Accessories-Electronics-Tools

-

School-Office-Supplies

School-Office-Supplies

-

Packaging-Printing

Packaging-Printing

-

Mother-Kids-Toys

Mother-Kids-Toys

-

Business-Services

Business-Services

-

Commercial-Equipment-Machinery

Commercial-Equipment-Machinery

-

Apparel-Accessories

Apparel-Accessories

-

Security

Security

-

Shoes-Accessories

Shoes-Accessories

-

Vehicle-Parts-Accessories

Vehicle-Parts-Accessories

-

Jewelry-Eyewear-Watches-Accessories

Jewelry-Eyewear-Watches-Accessories

-

Lights-Lighting

Lights-Lighting

-

Fabric-Textile-Raw-Material

Fabric-Textile-Raw-Material

-

Fabrication-Services

Fabrication-Services

-

Industrial-Machinery

Industrial-Machinery

-

Consumer-Electronics

Consumer-Electronics

-

Electrical-Equipment-Supplies

Electrical-Equipment-Supplies

-

Electronic-Components-Accessories-Telecommunications

Electronic-Components-Accessories-Telecommunications

-

Home-Appliances

Home-Appliances

-

Beauty

Beauty

-

Chemicals

Chemicals

-

Rubber-Plastics

Rubber-Plastics

-

Metals-Alloys

Metals-Alloys

- Masonry Materials

- Curtain Walls & Accessories

- Earthwork Products

- Fireproofing Materials

- Heat Insulation Materials

- Plastic Building Materials

- Building Boards

- Soundproofing Materials

- Timber

- Waterproofing Materials

- Balustrades & Handrails

- Bathroom & Kitchen

- Flooring & Accessories

- Tiles & Accessories

- Door, Window & Accessories

- Fireplaces & Stoves

- Floor Heating Systems & Parts

- Stairs & Stair Parts

- Ceilings

- Elevators & Escalators

- Stone

- Countertops, Vanity Tops & Table Tops

- Mosaics

- Metal Building Materials

- Multifunctional Materials

- Ladders & Scaffoldings

- Mouldings

- Corner Guards

- Decorative Films

- Formwork

- Building & Industrial Glass

- Other Construction & Real Estate

- Wallpapers/Wall panels

- HVAC System & Parts

- Outdoor Facilities

- Prefabricated Buildings

- Festive & Party Supplies

- Bathroom Products

- Household Sundries

- Rain Gear

- Garden Supplies

- Household Cleaning Tools & Accessories

- Lighters & Smoking Accessories

- Home Storage & Organization

- Household Scales

- Smart Home Improvement

- Home Textiles

- Kitchenware

- Drinkware & Accessories

- Dinnerware, Coffee & Wine

- Home Decor

- Golf

- Fitness & Body Building

- Amusement Park Facilities

- Billiards, Board Game,Coin Operated Games

- Musical Instruments

- Outdoor Affordable Luxury Sports

- Camping & Hiking

- Fishing

- Sports Safety&Rehabilitation

- Ball Sports Equipments

- Water Sports

- Winter Sports

- Luxury Travel Equipments

- Sports Shoes, Bags & Accessories

- Cycling

- Other Sports & Entertainment Products

- Artificial Grass&Sports Flooring&Sports Court Equipment

- Scooters

- Food Ingredients

- Honey & Honey Products

- Snacks

- Nuts & Kernels

- Seafood

- Plant & Animal Oil

- Beverages

- Fruit & Vegetable Products

- Frog & Escargot

- Bean Products

- Egg Products

- Dairy Products

- Seasonings & Condiments

- Canned Food

- Instant Food

- Baked Goods

- Other Food & Beverage

- Meat & Poultry

- Confectionery

- Grain Products

- Feminie Care

- Hair Care & Styling

- Body Care

- Hands & Feet Care

- Hygiene Products

- Men's Grooming

- Laundry Cleaning Supplies

- Travel Size & Gift Sets

- Room Deodorizers

- Other Personal Care Products

- Pest Control Products

- Special Household Cleaning

- Floor Cleaning

- Kitchen & Bathroom Cleaning

- Oral Care

- Bath Supplies

- Yellow Pages

- Correction Supplies

- Office Binding Supplies

- Office Cutting Supplies

- Board Erasers

- Office Adhesives & Tapes

- Education Supplies

- Pencil Cases & Bags

- Notebooks & Writing Pads

- File Folder Accessories

- Calendars

- Writing Accessories

- Commercial Office Supplies

- Pencil Sharpeners

- Pens

- Letter Pad/Paper

- Paper Envelopes

- Desk Organizers

- Pencils

- Markers & Highlighters

- Filing Products

- Art Supplies

- Easels

- Badge Holder & Accessories

- Office Paper

- Printer Supplies

- Book Covers

- Other Office & School Supplies

- Stationery Set

- Boards

- Clipboards

- Stamps

- Drafting Supplies

- Stencils

- Electronic Dictionary

- Books

- Map

- Magazines

- Calculators

- Baby & Toddler Toys

- Educational Toys

- Classic Toys

- Dress Up & Pretend Play

- Toy Vehicle

- Stuffed Animals & Plush Toys

- Outdoor Toys & Structures

- Balloons & Accessories

- Baby Food

- Children's Clothing

- Baby Supplies & Products

- Maternity Clothes

- Kids Shoes

- Baby Care

- Novelty & Gag Toys

- Dolls & Accessories

- Puzzle & Games

- Blocks & Model Building Toys

- Toddler Clothing

- Baby Clothing

- Kids' Luggage & Bags

- Arts, Crafts & DIY Toys

- Action & Toy Figures

- Baby Appliances

- Hobbies & Models

- Remote Control Toys

- Promotional Toys

- Pregnancy & Maternity

- Hygiene Products

- Kid's Textile&Bedding

- Novelty & Special Use

- Toy Weapons

- Baby Gifts

- Baby Storage & Organization

- Auto Drive Systems

- ATV/UTV Parts & Accessories

- Marine Parts & Accessories

- Other Auto Parts

- Trailer Parts & Accessories

- Auto Transmission Systems

- Train Parts & Accessories

- Universal Parts

- Railway Parts & Accessories

- Auto Brake Systems

- Aviation Parts & Accessories

- Truck Parts & Accessories

- Auto Suspension Systems

- Auto Lighting Systems

- New Energy Vehicle Parts & Accessories

- Auto Steering Systems

- Wheels, Tires & Accessories

- Bus Parts & Accessories

- Auto Performance Parts

- Cooling System

- Go-Kart & Kart Racer Parts & Accessories

- Air Conditioning Systems

- Heavy Duty Vehicle Parts & Accessories

- Auto Electrical Systems

- Auto Body Systems

- Auto Engine Systems

- Container Parts & Accessories

- Motorcycle Parts & Accessories

- Refrigeration & Heat Exchange Equipment

- Machine Tool Equipment

- Food & Beverage Machinery

- Agricultural Machinery & Equipment

- Apparel & Textile Machinery

- Chemical Machinery

- Packaging Machines

- Paper Production Machinery

- Plastic & Rubber Processing Machinery

- Industrial Robots

- Electronic Products Machinery

- Metal & Metallurgy Machinery

- Woodworking Machinery

- Home Product Manufacturing Machinery

- Machinery Accessories

- Environmental Machinery

- Machinery Service

- Electrical Equipment Manufacturing Machinery

- Industrial Compressors & Parts

- Tobacco & Cigarette Machinery

- Production Line

- Used Industrial Machinery

- Electronics Production Machinery

- Other Machinery & Industrial Equipment

- Camera, Photo & Accessories

- Portable Audio, Video & Accessories

- Television, Home Audio, Video & Accessories

- Video Games & Accessories

- Mobile Phone & Accessories

- Electronic Publications

- Earphone & Headphone & Accessories

- Speakers & Accessories

- Smart Electronics

- TV Receivers & Accessories

- Mobile Phone & Computer Repair Parts

- Chargers, Batteries & Power Supplies

- Used Electronics

- VR, AR, MR Hardware & Software

- Projectors & Presentation Equipments

- Other Consumer Electronics

- Cables & Commonly Used Accessories

- Computer Hardware & Software

- Displays, Signage and Optoelectronics

- Discrete Semiconductors

- Wireless & IoT Module and Products

- Telecommunications

- Connectors, Terminals & Accessories

- Development Boards, Electronic Modules and Kits

- Circuit Protection

- Sensors

- Isolators

- Audio Components and Products

- Integrated Circuits

- Power Supplies

- Relays

- RF, Microwave and RFID

- Electronic Accessories & Supplies

- Passive Components

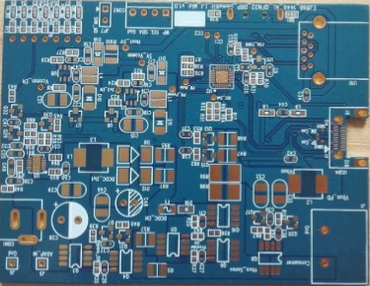

- PCB & PCBA

- Air Quality Appliances

- Home Appliance Parts

- Heating & Cooling Appliances

- Small Kitchen Appliances

- Laundry Appliances

- Water Heaters

- Water Treatment Appliances

- Refrigerators & Freezers

- Personal Care & Beauty Appliances

- Major Kitchen Appliances

- Cleaning Appliances

- Second-hand Appliances

- Smart Home Appliances

- Other Home Appliances

- Energy Chemicals

- Inorganic Chemicals

- Basic Organic Chemicals

- Agrochemicals

- Admixture & Additives

- Catalysts & Chemical Auxiliary Agents

- Pigments & Dyestuff

- Coating & Paint

- Daily Chemicals

- Polymer

- Organic Intermediate

- Adhesives & Sealants

- Chemical Waste

- Biological Chemical Products

- Surface Treatment Chemicals

- Painting & Coating

- Chemical Reagents

- Flavor & Fragrance

- Non-Explosive Demolition Agents

- Other Chemicals

- Custom Chemical Services

The Role of Controlled Impedance in Modern PCBs How Precise Tuning Affects Electronic Device Performance and Signal Clarity

In the rapidly evolving landscape of electronics, the demand for higher speeds, greater functionality, and miniaturized devices has never been more intense. At the heart of this technological advancement lies the printed circuit board (PCB), the fundamental platform that interconnects all electronic components. While often perceived as a simple carrier for chips and traces, the modern PCB is a sophisticated engineering feat where signal integrity is paramount. This brings us to a critical, yet sometimes overlooked, concept: controlled impedance. Imagine a high-speed data line in a smartphone or a server; as signals race across these pathways at gigahertz frequencies, they are not merely electrical currents but electromagnetic waves. If the pathway's characteristics do not match the signal's expectations, reflections, distortions, and data errors occur, much like an echo disrupting a conversation in a mismatched hallway. This article delves into the pivotal role of controlled impedance in modern PCBs, exploring how its precise tuning is not just a manufacturing specification but a cornerstone for ensuring electronic device performance, reliability, and crystal-clear signal clarity in our interconnected world.

The Fundamental Principles of Impedance in PCB Traces

To understand controlled impedance, one must first grasp the concept of impedance itself. In simple terms, impedance (Z) is the measure of opposition a circuit presents to the flow of alternating current (AC). It extends the idea of resistance (for direct current) to include both resistance and reactance, which arises from the capacitance and inductance inherent in any conductor. In a PCB, a trace is not just a wire; it forms a transmission line with its reference plane (a ground or power layer). This structure has characteristic impedance, determined by its physical geometry and the properties of the PCB materials.

The key parameters influencing this characteristic impedance include the trace width (W), the thickness of the dielectric material separating the trace from its reference plane (H), the dielectric constant (Er or Dk) of that insulating material, and the trace thickness (T). Even the presence of a solder mask can alter the impedance. When a signal travels along a trace, it seeks a consistent impedance path. If the impedance remains uniform, the signal propagates cleanly. However, any sudden change—a via, a bend, or a connection to a component—creates an impedance discontinuity. At high frequencies, these discontinuities cause signal reflections, where part of the signal energy bounces back toward the source, interfering with the original signal and leading to degradation.

The Critical Impact on High-Speed Signal Integrity

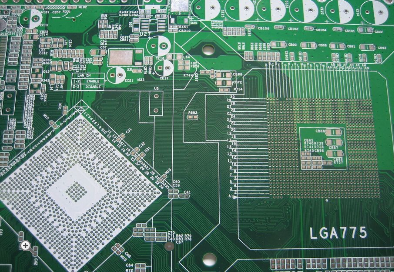

The necessity for controlled impedance becomes starkly apparent in high-speed digital and high-frequency analog circuits. In devices such as routers, graphics processors, and 5G communication modules, signals are comprised of fast-edged pulses containing a broad spectrum of frequencies. For these signals to be accurately received, the integrity of their shape and timing must be preserved. Precise impedance control ensures that the transmission line behavior of PCB traces is predictable and matched to the driver and receiver components' designed impedance, typically 50 ohms for single-ended lines or 100 ohms for differential pairs.

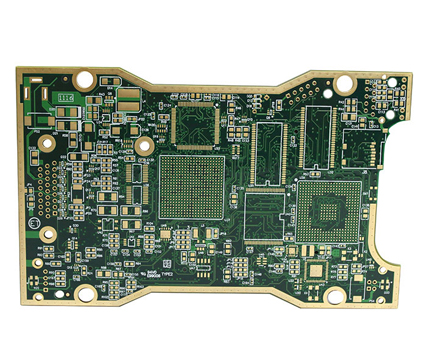

Without this control, signal integrity issues manifest in several detrimental ways. Reflections caused by impedance mismatches can lead to overshoot, undershoot, and ringing on the signal waveform. This noise margin reduction increases the bit error rate (BER) in digital systems, potentially causing data corruption. For timing-critical signals like clock lines, these reflections can introduce jitter—small timing variations—that can cause synchronization failures between components. In high-speed serial links like PCI Express, USB 3.0, or DDR memory buses, even minor impedance variations can close the "eye diagram," a visual tool for assessing signal quality, making data recovery at the receiver unreliable or impossible.

Precise Tuning: From Design to Manufacturing

Achieving controlled impedance is a meticulous process that spans the entire PCB development cycle, from initial design to final fabrication. It begins in the electronic design automation (EDA) software, where designers define impedance targets for critical nets. Using built-in calculators or field solvers, they adjust trace width, spacing (for differential pairs), and layer stack-up configuration to meet these targets based on the chosen laminate material's dielectric constant. This stack-up design, specifying the sequence and thickness of copper and dielectric layers, is the blueprint for impedance control.

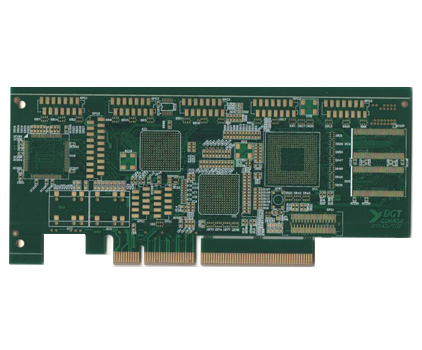

The baton then passes to the PCB manufacturer, where precision engineering takes center stage. Maintaining consistent impedance requires extraordinary process control. Variations in etching can alter trace width; inconsistencies in laminate thickness or dielectric constant can shift impedance values. Advanced manufacturers use techniques like laser direct imaging (LDI) for more accurate pattern transfer and employ real-time process monitoring. They often produce test coupons—small sections on the panel containing trace structures—to perform Time-Domain Reflectometry (TDR) tests. TDR sends a fast pulse down the trace and analyzes reflections to measure the actual impedance profile, verifying it falls within the specified tolerance, often as tight as ±5% or even ±3% for demanding applications.

Consequences for Overall Device Performance and Reliability

The ripple effects of well-executed impedance control extend far beyond clean signals on a scope; they directly define the performance ceiling and reliability of the end product. In wireless communication devices, such as smartphones and IoT sensors, controlled impedance in RF transmission lines ensures maximum power transfer from the transceiver to the antenna and minimizes unwanted signal loss or radiation. This translates to stronger signal reception, longer battery life, and compliance with stringent electromagnetic compatibility (EMC) regulations by reducing electromagnetic interference (EMI).

Furthermore, in complex systems like network switches or automotive ADAS (Advanced Driver-Assistance Systems), multiple high-speed channels operate in parallel. Crosstalk, where a signal on one trace induces noise on an adjacent trace, is exacerbated by poor impedance control. Properly tuned impedance, coupled with careful spacing and grounding, minimizes crosstalk, allowing for higher data throughput and system stability. Ultimately, this engineering rigor reduces post-production failures, minimizes the need for costly design revisions, and builds a foundation for devices that perform reliably under real-world conditions, fostering trust in the technology that powers our daily lives.

REPORT